Revolutionizing Industries: The Impact of Mechatronics on Modern Engineering

Introduction

In the 21st century, industries across the globe are undergoing significant transformations facilitated by advancements in technology. Among these advancements, mechatronics has emerged as a pivotal field, merging mechanical engineering, electronics, computer science, and control engineering to create more efficient, automated, and intelligent systems. This article delves into the profound impact of mechatronics on modern engineering and its role in revolutionizing various industries, including manufacturing, healthcare, automotive, and beyond.

Understanding Mechatronics

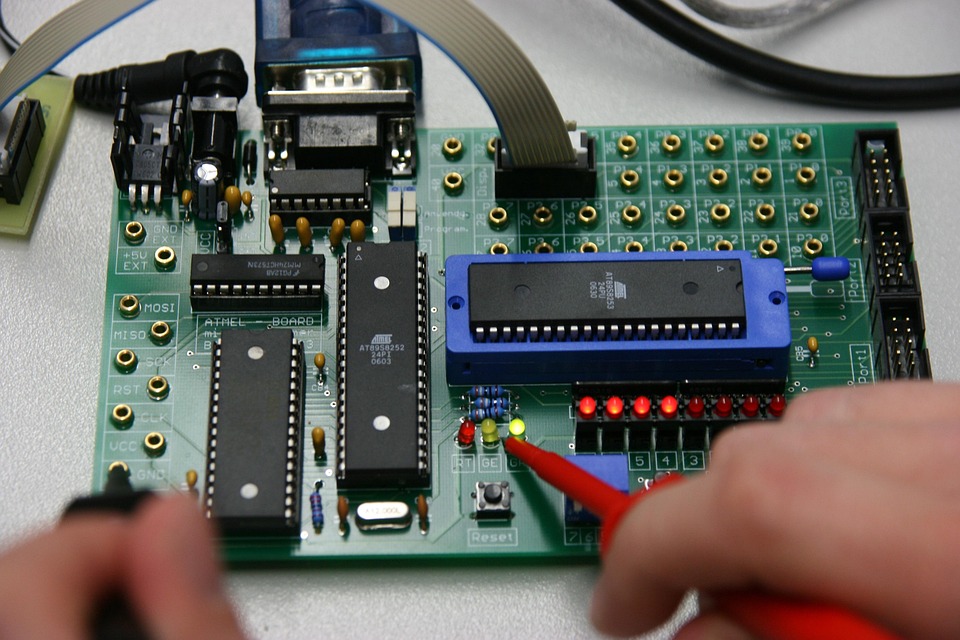

Definition and Components

Mechatronics is an interdisciplinary field that combines elements from various engineering domains. At its core, mechatronics integrates mechanical design, electronic control, and computer systems to improve the functionality of products and processes. The primary components of mechatronic systems typically include:

- Mechanical Systems: The physical structure and mechanics that perform work.

- Electronics: Components such as sensors, actuators, and microcontrollers that provide control and feedback.

- Computer Science: Software and algorithms that facilitate communication and decision-making processes.

The synergy of these components leads to the development of smart, automated systems capable of performing intricate tasks with precision and efficiency.

Historical Context

The term "mechatronics" was first coined in Japan in the 1960s, representing a shift toward integrating mechanical and electronic engineering. Over the decades, advancements in computing and microelectronics propelled the field forward, leading to innovations in robotics, automation, and intelligent systems [^1].

The Role of Mechatronics in Key Industries

Manufacturing Sector

Automation and Robotics

The manufacturing industry has been at the forefront of embracing mechatronics, particularly in the realm of automation and robotics. Automated systems designed with mechatronics principles can streamline production processes, reduce errors, and increase output.

-

Robotic Arm Applications: In assembly lines, robotic arms equipped with sensors and control systems can carry out repetitive tasks such as welding, painting, and assembly with remarkable precision. This not only enhances productivity but also minimizes workplace injuries associated with manual labor [^2].

- Flexible Manufacturing Systems (FMS): Mechatronic systems enable the creation of flexible manufacturing setups that can easily adapt to changes in product design and demand. This adaptability is crucial in today’s fast-paced market environment, where consumer preferences can shift rapidly [^3].

Predictive Maintenance

Mechatronics plays a significant role in predictive maintenance—an approach that uses data collected from machines to predict failures before they occur. By integrating sensors that monitor machine health and performance, manufacturers can reduce downtime and maintenance costs [^4].

Healthcare Sector

Medical Robotics

In healthcare, mechatronics has transformed surgical procedures through the development of advanced medical robots. These robotic systems offer enhanced precision, control, and visualization for surgeons, significantly improving patient outcomes.

-

Robotic Surgery: Systems such as the da Vinci Surgical System allow surgeons to perform minimally invasive procedures with greater dexterity. The integration of mechatronics enables surgeons to manipulate robotic instruments through a console, translating their movements into precise actions within the patient’s body [^5].

- Rehabilitation Robotics: Robotic exoskeletons assist patients recovering from strokes or spinal cord injuries, enabling them to regain mobility. These mechatronic devices leverage sensors and actuators to provide support and feedback, facilitating rehabilitation [^6].

Medical Imaging

Mechatronics has also enhanced medical imaging technologies. Devices such as MRI and CT scanners utilize mechatronic systems to achieve high-resolution imaging and accurate diagnostics, improving the overall quality of patient care [^7].

Automotive Industry

Autonomous Vehicles

The automotive industry is undergoing a significant transformation with the advent of autonomous vehicles, heavily reliant on mechatronic systems.

-

Sensor Integration: Autonomous vehicles use an array of sensors (LiDAR, cameras, radar) to gather real-time data about their surroundings. Mechatronic systems process this information to make driving decisions [^8].

- Vehicle-to-Everything (V2X) Communication: Mechatronics enables the integration of vehicles with infrastructure, pedestrians, and other vehicles to improve safety and traffic efficiency. This interconnectedness is paving the way for smarter urban mobility solutions [^9].

Advanced Driver-Assistance Systems (ADAS)

ADAS employs mechatronic principles to enhance vehicle safety and comfort. Features such as adaptive cruise control, lane-keeping assistance, and automatic braking systems rely on complex algorithms and sensor data to operate, significantly reducing the likelihood of accidents [^10].

Aerospace and Defense

In the aerospace sector, mechatronics is revolutionizing aircraft design, maintenance, and operations.

-

Fly-by-Wire Systems: Modern aircraft use fly-by-wire control systems that convert a pilot’s inputs into electronic signals, allowing for greater precision and reliability [^11].

- Unmanned Aerial Vehicles (UAVs): UAVs, or drones, utilize mechatronics for navigation, control, and payload delivery, making them indispensable tools in both commercial and military applications [^12].

Agriculture

The integration of mechatronics in agriculture has led to the development of precision farming techniques, enhancing crop management and yield.

-

Automated Farming Equipment: Tractors and harvesters equipped with GPS and sensors can perform tasks such as planting, watering, and harvesting with high precision [^13]. These automated systems optimize resources and reduce waste.

- Drones in Agriculture: Drones are used for monitoring crop health, soil conditions, and irrigation needs, enabling farmers to make data-driven decisions [^14].

Challenges and Opportunities

Challenges

Despite the numerous benefits of mechatronics, several challenges must be addressed to fully leverage its potential:

-

Skill Gap: The demand for skilled professionals in mechatronics is rising, but there is a noticeable skill gap. Educational institutions must adapt curricula to prepare students for jobs in this interdisciplinary field [^15].

-

Integration Issues: Integrating mechatronic systems with existing infrastructures can pose technical challenges. Ensuring compatibility and reliability of systems is crucial for successful implementation [^16].

- Cost of Implementation: While mechatronic systems can lead to long-term savings and efficiency gains, the initial investment required for development and deployment can be a barrier for some businesses [^17].

Opportunities

The future of mechatronics is promising, with numerous opportunities for growth and innovation:

-

Smart Cities: As urban populations grow, mechatronic systems can contribute to the development of smart cities through advanced transportation systems, energy management, and public safety [^18].

-

Sustainable Practices: Mechatronics can play a vital role in promoting sustainability by optimizing resource use and reducing energy consumption across various industries [^19].

- Industry 4.0: The fourth industrial revolution is characterized by the integration of digital technologies in manufacturing. Mechatronics is essential for enabling smart factories that emphasize automation, data exchange, and IoT [^20].

Conclusion

Mechatronics is a driving force behind the transformation of modern engineering across various industries. Its integration of mechanical, electronic, and computational systems enables the development of innovative solutions that enhance efficiency, precision, and adaptability. As we navigate the complexities of the 21st century, the role of mechatronics will continue to be pivotal in addressing industry challenges and unlocking new opportunities.

By embracing mechatronics, industries can revolutionize their processes, create smart solutions, and ultimately contribute to a more sustainable and efficient future.

Add Comment