Smart Machines: The Role of Mechatronics in Automation and Robotics

Introduction

In an era characterized by rapid technological advancement, the interplay between mechanical engineering, electronics, computer science, and control engineering has culminated in the development of smart machines. This convergence is epitomized in the field of mechatronics, which plays a pivotal role in automation and robotics. As industries seek to optimize efficiency, safety, and productivity, the importance of mechatronics becomes increasingly apparent. This article delves into the critical components, applications, and future implications of mechatronics in creating smart machines that transform sectors from manufacturing to healthcare.

1. Understanding Mechatronics

1.1 Definition and Components

Mechatronics is an interdisciplinary branch of engineering that encompasses mechanical engineering, electronics, computer science, control theory, and systems design engineering. The term is a portmanteau of "mechanics" and "electronics," highlighting its focus on the synergy between these traditionally separate disciplines. At its core, mechatronics aims to create intelligent systems and products that integrate these domains to achieve a higher level of functionality and efficiency.

Key components of mechatronic systems include:

-

Sensors: Devices that detect physical properties such as temperature, speed, and pressure, then convert them into signals that can be read by other devices.

-

Actuators: Mechanical devices that convert electrical energy into physical motion, often found in robotic arms or automated machinery.

-

Control Systems: Algorithms and software that regulate the functioning of machines and systems to ensure they operate as intended.

- Microcontrollers and microprocessors: Embedded systems that execute the control algorithms, crucial for real-time response and decision-making.

1.2 Historical Evolution

The roots of mechatronics trace back to the early 20th century with the advent of devices like the first mechanical computers. However, the term "mechatronics" was coined in the late 1960s by Dr. Hiroshi Makino in Japan. Since then, advancements in microelectronics and computing power have accelerated its development, especially in automated systems and robotics. The integration of mechanization with intelligent electronics has led to systems capable of learning from their environments and adapting their behaviors, marking a paradigm shift in engineering practices.

2. Mechatronics in Automation

2.1 Automation Defined

Automation refers to the use of control systems for operating equipment in processes such as machinery, boilers, and heat treating ovens in factories, switching on telephone networks, steering and stabilization of ships, aircraft, and other applications. Mechatronics has revolutionized automation through its interdisciplinary approach, allowing for the seamless integration of mechanical systems and electronic controls.

2.2 Applications of Mechatronics in Automation

Certain applications of mechatronics in automation showcase its transformative potential across various industries:

2.2.1 Manufacturing

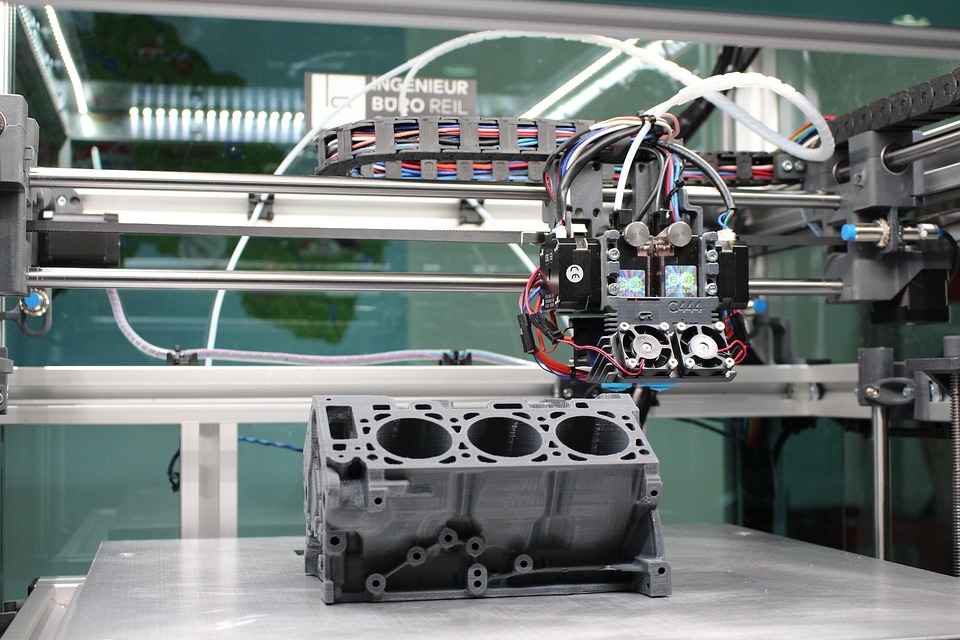

In manufacturing, mechatronic systems are integral to creating flexible automation solutions. Robotic arms equipped with advanced sensors and actuators can adapt to different tasks and environments, significantly enhancing production processes. Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems offer real-time monitoring and control, streamlining workflows and reducing operational costs.

2.2.2 Automotive Industry

The automotive industry has embraced mechatronics through the development of advanced driver-assistance systems (ADAS). These systems utilize sensors and control algorithms to enhance vehicle safety, improve fuel efficiency, and facilitate autonomous driving capabilities. The integration of mechatronic principles in both gasoline and electric vehicles is essential for developing smart transportation systems.

2.2.3 Smart Homes

The concept of smart homes exemplifies the application of mechatronics in automation. Home automation systems utilize interconnected devices and smart sensors to enable users to control lighting, security, heating, and appliances. Through the use of mechatronic components, these systems improve energy efficiency and enhance the overall quality of life.

2.3 Challenges in Automation

While the potential of mechatronics in automation is immense, several challenges remain. The complexity of integrating various systems can lead to increased costs and potential for errors. Additionally, the need for cybersecurity measures to protect automated systems from unauthorized access is a growing concern. Moreover, as tasks become more automated, the implications for the workforce must be carefully managed.

3. Mechatronics in Robotics

3.1 The Intersection of Mechatronics and Robotics

Robotics is a field that heavily relies on mechatronics to create robots that can operate autonomously or semi-autonomously. These machines are designed to carry out tasks that are either too dangerous or too complex for humans. The integration of sensors, actuators, and control systems enables robots to interact with their environments intelligently and perform a variety of tasks.

3.2 Types of Robots

3.2.1 Industrial Robots

Industrial robots are widely utilized in manufacturing settings for tasks such as welding, painting, assembly, and material handling. They are typically programmed to perform repetitive tasks with high precision. Mechatronics enables these robots to adapt to changes in the production line and perform multiple tasks, enhancing flexibility.

3.2.2 Service Robots

Service robots are designed for roles outside traditional manufacturing, including healthcare, hospitality, and customer service. These robots often require advanced sensory capabilities and artificial intelligence to interact effectively with humans. The mechatronic integration allows them to perform complex tasks such as surgery assistance or concierge services in hotels.

3.2.3 Autonomous Robots

Autonomous robots, including drones and self-driving vehicles, rely heavily on mechatronics and AI to operate without human intervention. These robots utilize sensors and cameras to perceive their environments and make real-time decisions based on pre-defined algorithms. The mechatronic systems embedded in these robots are crucial for navigating unpredictable scenarios.

3.3 The Role of AI in Robotics

Artificial Intelligence (AI) further enhances the capabilities of mechatronic robots. Machine learning algorithms enable robots to learn from their experiences and improve their performance over time. For example, a robotic vacuum cleaner equipped with AI can map a home, recognize obstacles, and optimize its cleaning path. The integration of AI with mechatronics is swiftly changing the landscape of robotics, making machines smarter and more adaptable.

3.4 Future Trends in Robotics

As technology continues to evolve, several trends are poised to shape the future of robotics and mechatronics:

-

Collaborative Robots (Cobots): Designed to work alongside human workers, cobots enhance tasks without replacing jobs. Their integration in manufacturing workplaces highlights the importance of human-robot interaction.

-

Soft Robotics: This subfield focuses on creating robots from compliant materials, making them safer for interaction with humans and ideal for delicate tasks.

- Swarm Robotics: Inspired by the behavior of social insects, swarm robotics involves multiple robots working together to complete tasks efficiently. This approach can revolutionize industries such as agriculture and disaster recovery.

4. Case Studies of Mechatronics in Action

4.1 Case Study 1: Automotive Manufacturing

Ford Motor Company has integrated mechatronics into its automotive manufacturing process. The use of robotic arms equipped with sensors for quality control and assembly has resulted in higher productivity and decreased error rates. The implementation of PLCs enables real-time monitoring of production lines, ensuring that any issues can be addressed promptly.

4.2 Case Study 2: Healthcare Robotics

The da Vinci Surgical System is a prime example of how mechatronics transforms healthcare. This robotic surgical system allows surgeons to perform minimally invasive surgeries with enhanced precision, benefiting from mechatronic design principles such as advanced control algorithms and robotic arms that mimic human hand movements.

4.3 Case Study 3: Agricultural Automation

In agriculture, mechatronics plays a crucial role in modernizing practices. Automated tractors and drones equipped with sensors allow for precision farming, including soil analysis, crop monitoring, and efficient irrigation. These smart machines leverage mechatronic systems to optimize resource use and improve yields.

5. Future Implications and Ethical Considerations

As the field of mechatronics continues to innovate, several ethical considerations need to be addressed regarding automation and robotics:

5.1 Job Displacement

The rise of automation raises concerns about job displacement in various industries. While automation can lead to increased efficiency and reduced costs, it may also result in reduced job opportunities for low-skilled workers. Societies must find ways to balance technological advancement with workforce development.

5.2 Security and Privacy

As smart machines gather vast amounts of data, the implications for security and privacy become paramount. Protecting sensitive information from cyber threats is a challenge that requires robust cybersecurity measures and ethical standards.

5.3 Accountability and Liability

The question of responsibility arises when machines operate autonomously. In the event of an accident caused by an autonomous vehicle, for example, determining liability can become complicated. As technology progresses, legal frameworks must adapt to address these challenges.

6. Conclusion

Mechatronics has become a foundational pillar in the development of smart machines, significantly impacting automation and robotics. From advancing manufacturing processes to enhancing healthcare solutions, the integration of mechanical and electronic systems holds immense potential for transforming industries. As we navigate the complex landscape of technological innovation, it is crucial to address the ethical implications and challenges that arise. The future of mechatronics will undoubtedly shape our world, paving the way for smarter, safer, and more efficient systems.

[^modern_footnote_source]: For further reading and detailed information on specific cases and advancements in mechatronics, refer to industry journals, conferences, and specialized publications focusing on automation and robotics.

Add Comment