The Future of Manufacturing: How Mechatronics Engineering is Leading the Charge

The manufacturing sector is undergoing a radical transformation, driven by advancements in technology, automation, and digitalization. At the heart of this revolution is mechatronics engineering, a multidisciplinary field that merges mechanical engineering, electronics, computer science, and control engineering. This article explores how mechatronics engineering is defining the future of manufacturing, impacting productivity, flexibility, and innovation.

Understanding Mechatronics Engineering

Definition and Scope

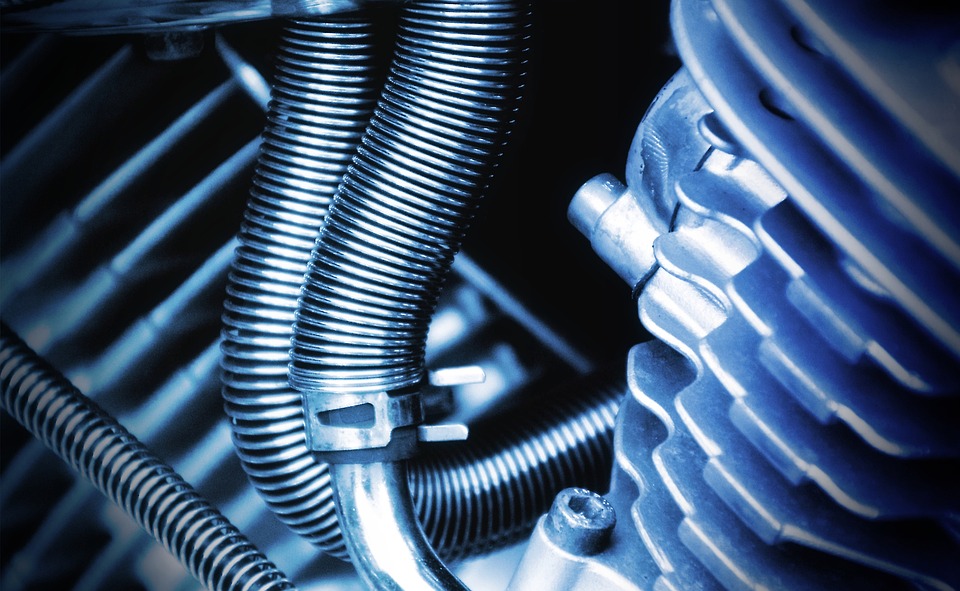

Mechatronics engineering is a broad discipline that integrates mechanical and electrical engineering with computer science to create intelligent systems and products. This field encompasses robotics, automation, control systems, and embedded systems. The versatility of mechatronics allows engineers to work across various sectors, from automotive to aerospace, consumer electronics, and beyond.

Historical Context

The roots of mechatronics can be traced back to the 1960s when the integration of mechanical systems with electronics began gaining traction. As computers became more accessible, engineers started to realize the potential for creating systems that could think and react autonomously. Over the decades, advancements in sensor technology, materials science, and computing power have propelled mechatronics forward, establishing it as a critical component of modern manufacturing.

The Role of Mechatronics in Modern Manufacturing

Automation and Robotics

Automation is a defining characteristic of the modern manufacturing landscape. Mechatronics engineering plays a vital role in the design and development of robotic systems that improve efficiency and precision. Robots equipped with sophisticated sensors and control systems can perform repetitive tasks with high accuracy, reducing human error and lowering production costs.

Collaborative Robots (Cobots)

The advent of collaborative robots (cobots) is another milestone in manufacturing. Cobots are designed to work alongside human operators, enhancing productivity and safety. Their integration into the workforce emphasizes the role of mechatronics in bridging the gap between humans and machines.

Smart Manufacturing and Industry 4.0

The Fourth Industrial Revolution, or Industry 4.0, heralds an era of interconnected manufacturing processes driven by data analytics and IoT (Internet of Things). Mechatronics engineering is central to smart manufacturing initiatives, facilitating real-time communication between machines, systems, and employees. By harnessing data, manufacturers can optimize their operations, predict maintenance needs, and improve overall product quality.

Additive Manufacturing (3D Printing)

Mechatronics has directly influenced the development of additive manufacturing technologies, which allow for the layer-by-layer construction of parts and products. This method offers unparalleled design flexibility, enabling manufacturers to create complex geometries that traditional manufacturing methods cannot achieve. The application of robotics in additive manufacturing significantly reduces human involvement, streamlining the production process.

Advanced Materials and Manufacturing Techniques

The integration of mechatronics in manufacturing opens new doors for using advanced materials such as composites and smart materials. These materials enhance the performance of products and reduce manufacturing waste. For example, mechatronics systems can precisely control processes like extrusion or molding, allowing for better material utilization and efficiency.

Predictive Maintenance and Quality Control

Predictive maintenance, driven by IoT sensors and data analytics, is becoming increasingly important in manufacturing. Mechatronics systems facilitate the monitoring of equipment health in real-time, enabling manufacturers to predict failures before they occur, thus avoiding costly downtime. Furthermore, mechatronics solutions support automated quality control, ensuring that defects are detected early in the production process.

Challenges and Opportunities

Workforce Implications

While mechatronics engineering fosters innovation, it also poses challenges for the workforce. The increasing automation of manufacturing processes may lead to job displacement for low-skill workers. However, it also opens up opportunities for skilled professionals in mechatronics and related fields. Manufacturers must invest in training and reskilling programs to prepare their workforce for this transition.

Technological Complexity

The integration of advanced technologies in manufacturing necessitates a high level of technical expertise. The complexity of mechatronics systems requires engineers to possess a multidisciplinary skill set. Organizations must prioritize education and training in mechatronics to ensure they have access to the necessary talent pool.

Cybersecurity Concerns

As manufacturing becomes more interconnected through IoT and smart systems, cybersecurity risks grow. Mechatronics engineering must address these vulnerabilities by developing secure systems to protect sensitive data and operations from cyber threats. Manufacturers need to adopt strong security protocols and collaborate with cybersecurity experts to safeguard their systems.

Sustainability

The future of manufacturing hinges on sustainability, and mechatronics engineering can lead the charge in minimizing environmental impact. Smart systems can optimize resource usage and energy consumption, while additive manufacturing can reduce waste. Engineers are continually exploring ways to create processes that are both efficient and environmentally friendly.

Case Studies

Automotive Industry

The automotive sector has embraced mechatronics to revolutionize production methodologies. Automated assembly lines equipped with robotic arms increase speed and improve precision. Furthermore, advanced driver-assistance systems (ADAS) rely heavily on mechatronics for functionality like lane-keeping assistance and adaptive cruise control.

Aerospace Sector

In aerospace manufacturing, light-weight composites and 3D printing are utilized in constructing parts that are both strong and lightweight. Mechatronics systems manage complex processes, such as robotic assembly and quality control, ensuring that safety standards are met without compromising efficiency.

Consumer Electronics

The consumer electronics industry has seen rapid advancement due to mechatronics engineering. Products like smartphones and smart home devices depend on intricate mechatronics systems for functionality, design, and performance. Automation in production lines allows for high flexibility, enabling manufacturers to adapt quickly to changing consumer demands.

Medical Devices

Mechatronics plays a significant role in designing and manufacturing medical devices, from diagnostic equipment to surgical robots. These devices must meet stringent quality and safety standards, and mechatronics systems ensure precision and reliability in their operation.

Future Trends in Mechatronics Engineering

Artificial Intelligence and Machine Learning Integration

The integration of AI and machine learning with mechatronics will lead to smarter systems capable of self-learning and optimization. For instance, AI can analyze data from robotic operations to fine-tune processes and improve efficiency continuously.

Enhanced Human-Machine Interaction

As mechatronics systems become more intuitive, we can expect improved human-machine interaction. Advanced interfaces, including augmented reality (AR) and virtual reality (VR), will enable operators to make better-informed decisions and enhance their productivity.

Miniaturization and Flexibility

Future mechatronics systems will likely trend toward miniaturization, creating smaller, more efficient devices that maintain or increase performance. Additionally, flexible manufacturing systems capable of rapid reconfiguration will become more prevalent, allowing manufacturers to switch production lines quickly to meet market demands.

Global Supply Chain Optimization

Mechatronics will enable smarter global supply chain management by leveraging real-time data analytics. This capability will lead to improved inventory management, reduced lead times, and enhanced responsiveness to market changes.

Conclusion

As manufacturing continues to evolve, mechatronics engineering is poised to lead the charge in driving innovation, efficiency, and sustainability. By focusing on the integration of advanced technologies, manufacturers can position themselves to thrive in a competitive global market. The future of manufacturing is bright, and mechatronics will undoubtedly play a critical role in shaping it.

References

- De Silva, C. W. (2005). Mechatronics: A Foundation Course. London: Springer.

- Nof, S. Y. (1999). Advances in Industrial Robotics. New York: Wiley.

- Groover, M. P. (2007). Industrial Robotics: Technology, Programming, and Applications. New York: McGraw-Hill.

- Koren, Y., et al. (2018). “The Future of Manufacturing: Intelligent Automation.” Proceedings of the National Academy of Sciences, 115(19), 4909-4914.

- Bock, T. (2015). “Smart Manufacturing for the Future.” Journal of Manufacturing Science and Engineering, 137(4), 1-12.

In this article, we have explored the myriad ways in which mechatronics engineering is shaping the future of manufacturing, highlighting its impact and the potential it offers for enhanced productivity and innovation. The challenges that accompany this transition cannot be overlooked, but with proactive measures, the manufacturing landscape can be made resilient and sustainable for future generations.

Add Comment